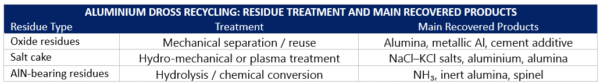

During aluminium dross recycling, the main goal is to recover metallic aluminium efficiently.

However, the process also generates non-metallic byproducts such as oxide residues (from mechanical pretreatment) and salt cake (from salt-assisted melting in rotary furnaces).

Proper handling and recycling of these residues are essential to achieve sustainable, zero-waste aluminium recovery.

1. OXIDE RESIDUES FROM MECHANICAL PRETREATMENT

1.1 Composition

Oxide residues primarily consist of aluminium oxides (Al₂O₃), minor metallic aluminium, and other oxides such as SiO₂, MgO, and Fe₂O₃. Typical composition:

- Al₂O₃: 60–75%

- Al metálico: 2–5%

- SiO₂, MgO, Fe₂O₃, CaO: Balance

1.2 Recycling and Reuse Methods

A. Remelting or Plasma Recovery

If the metallic aluminium content exceeds 5%, the oxide fraction can be reprocessed:

- Tilting rotary furnaces (TRF) can remelt oxides mixed with flux to recover remaining metal.

- Plasma or oxy-fuel furnaces can further extract entrapped metallic aluminium.

Recovery yield: up to 70% of residual metal.

B. Use in Cement and Steel Industries

The alumina-rich oxide fraction can be used as:

- Mineralizer or alumina source in Portland cement clinker production

- Fluxing additive in steelmaking slags for de-sulphurization and refining

C. Refractory and Ceramic Applications

Stabilized aluminium oxides can replace part of natural bauxite or alumina in:

- Refractory bricks

- Low-grade ceramics

- Thermal insulation products

D. Stabilization and Landfilling

If reuse is not feasible, the residues are hydrated and carbonated to neutralize reactivity before disposal as non-hazardous waste. Modern plants, however, aim for zero landfill by prioritizing reuse routes.

2. SALT CAKE (SALT SLAG) FROM ROTARY FURNACE OPERATIONS

2.1 Composition and Properties

Salt cake—also known as salt slag or black dross—is the solid residue from salt-assisted melting. It typically contains:

- Al₂O₃: 30–60%

- NaCl + KCl: 20–50%

- Al metálico: 3–10%

- AlN, MgO, SiO₂: Trace

It is reactive with water, forming ammonia (NH₃) and hydrogen (H₂) gases, and must be handled in a controlled environment.

2.2 Recycling and Recovery Methods

A. Hydro-Mechanical Salt Slag Processing

This is the most widely used industrial method

Process steps:

- 1. Crushing & screening to recover metallic aluminium.

- 2. Leaching with water to dissolve NaCl and KCl.

- 3. Hydrolysis of AlN (ammonia gas captured and neutralized).

- 4. Filtration & evaporation to recover salt solution for reuse

- 5. LSolid residue washed and neutralized for reuse or disposal.

Outputs:

- 80–90% salt recovery (reused in rotary furnaces).

- 5–10% metallic aluminium recovery.

- 30–40% inert oxide residue suitable for reuse in construction materials

B. Plasma or Thermal Treatment (Emerging)

High-temperature plasma or rotary kiln systems decompose AlN and volatilize salts for recovery.

Produces inert, alumina-rich solids suitable for reuse.

Advantages: zero liquid effluent

Limitation: high energy cost.

C. Chemical Conversion and Valorization

Research is developing chemical conversion of salt slag residues into useful materials:

- Alumina or aluminium hydroxide via alkaline leaching.

- Geopolymer and cementitious products through alkali activation.

- Spinel (MgAl₂O₄) synthesis for refractory applications.

These processes are still at pilot or early commercial scale but show strong sustainability potential.

3. TOWARDS ZERO-WASTE ALUMINIUM RECYCLING

By integrating oxide and salt slag recovery technologies, the aluminium industry can achieve over 98% material utilization.

Such integration turns recycling plants into closed-loop resource recovery facilities, minimizing environmental footprint and maximizing economic return.

4. CONCLUSION

After aluminium dross recycling, oxide residues and salt cake should not be viewed as waste but as secondary resources.

Through hydro-mechanical salt slag processing, oxide reuse in construction and metallurgy, and emerging chemical valorization technologies, the aluminium industry is moving toward zero-waste and full circularity.

Modern recycling plants increasingly operate not just as smelters, but as comprehensive resource recovery centers, closing the loop across every fraction of the process.

Does this topic interest you? Discover our thematic dossier:

→ Aluminium dross recycling: overview and key technical challenges