Dross pretreatment is the final phase in the comprehensive aluminium recycling strategy. Its objective is to increase the metallic concentration of the dross before melting, separating non-metallic impurities and oxides. This stage improves process performance and drastically reduces operating costs and waste generation.

1. Objective of the pretreatment

Transform a “lean” dross (30–40% aluminum) into a concentrate with more than 70% metal content. The process separates the unwanted fractions – oxides, ferrous residues and contaminants – maximizing the purity of the concentrate that will later be introduced into the rotary kiln.

2. Stages of the process

The pretreatment combines mechanical crushing, screening and particle size sorting operations:

1. Loading hopper and primary feeding.

2. Impact mill (primary): breaks the dross into fragments of 30–100 mm.

3. Screen 1: separates the coarse fraction (>100 mm) from the average fraction (1–30 mm).

4. Centrifugal Mill (Secondary): Refines the middle fraction and releases the trapped aluminum.

5. Sieve 2 and filtration: final separation of oxides and accumulation of dust in silos.

The result is a concentrated product >70% Al, ready for efficient melting.

3. Typical Operational Data

Product: white aluminum dross.

Density: 1.2–1.3 t/m³.

Inlet range: 0–500 mm; maximum weight per piece 100 kg.

Capacity: 10–40 t/h.

Final granulometry: >100 mm, 30–100 mm, 1–30 mm and 0–1 mm.

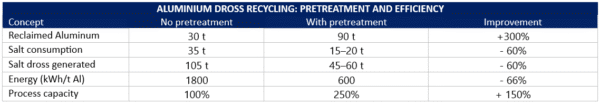

4. Technical and economic benefits

Pretreatment has a direct impact on efficiency indicators:

In addition, the process allows operating with lower overall energy consumption (400 kWh/t input) and increases plant availability by reducing shutdowns for cleaning or maintenance.

5. Sustainability and added value

Pretreatment not only improves metal recovery, but also reduces the environmental footprint of aluminum recycling:

– Decreases the volume of waste sent to landfill.

– Reduce the use of salts and aggressive flows.

– Optimizes traceability and emissions control.

– It favors the circular economy by reincorporating high-purity materials into the production cycle.

Conclusion

The combination of internal recycling of hot dross with pre-treatment is the most efficient and sustainable strategy for modern foundries. The result is a simultaneous improvement in metal performance, operating cost and environmental responsibility, positioning dross recycling as a fundamental pillar in the transition to the aluminum industry of the future.

Does this topic interest you? Discover our thematic dossier:

→ Aluminium dross recycling: overview and key technical challenges